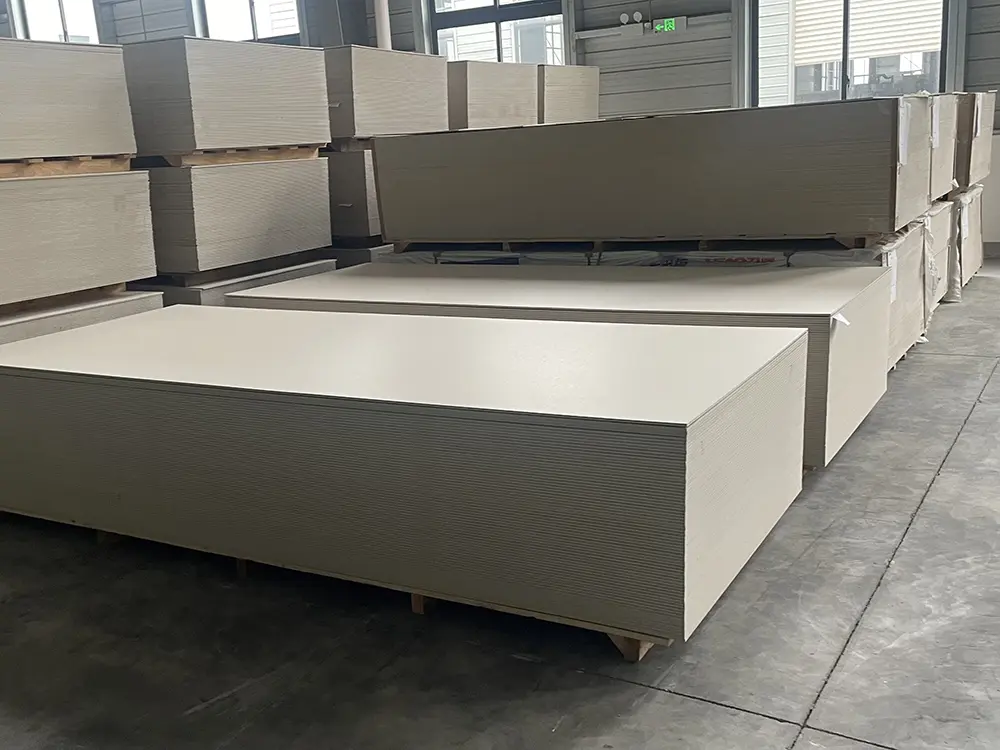

In recent years, the demand for UV Coated Fiber Cement Boards has surged, driven by their durability, aesthetic versatility, and eco-friendliness. According to a recent report from the Global Cement and Concrete Association, the global fiber cement market is expected to grow at a CAGR of 6.5% over the next five years, reaching an estimated value of $20 billion by 2026. This growth is largely attributed to the rising need for sustainable building materials that offer both performance and design flexibility. As manufacturers and builders increasingly prioritize high-quality materials, sourcing UV Coated Fiber Cement Boards from reputable suppliers worldwide becomes essential. This blog will explore effective strategies for sourcing these panels, ensuring that businesses can meet their construction needs while enhancing sustainability and aesthetics in their projects.

UV coating is a revolutionary process that enhances the durability and aesthetic appeal of fiber cement boards. The application of UV coatings provides several benefits, making the boards resistant to weathering, scratches, and other forms of damage. This advanced coating not only protects the surface but also enhances its visual quality by offering a range of finishes and colors. As a result, fiber cement boards with UV coatings are ideal for both exterior and interior applications, delivering longevity and style to construction projects.

When sourcing high-quality UV coated fiber cement boards, it’s crucial to consider a few tips to ensure you’re making the right choice. First, look for suppliers who utilize advanced UV curing technology, as this significantly improves the durability of the coating. Additionally, request samples to assess the finish and resistance properties before committing to larger orders. Lastly, always inquire about the environmental certifications of the coatings used, as sustainability is becoming increasingly important in modern construction.

By focusing on suppliers who prioritize quality and innovation in their UV coating processes, you can elevate your projects with fiber cement boards that stand up to the test of time while offering visual excellence.

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

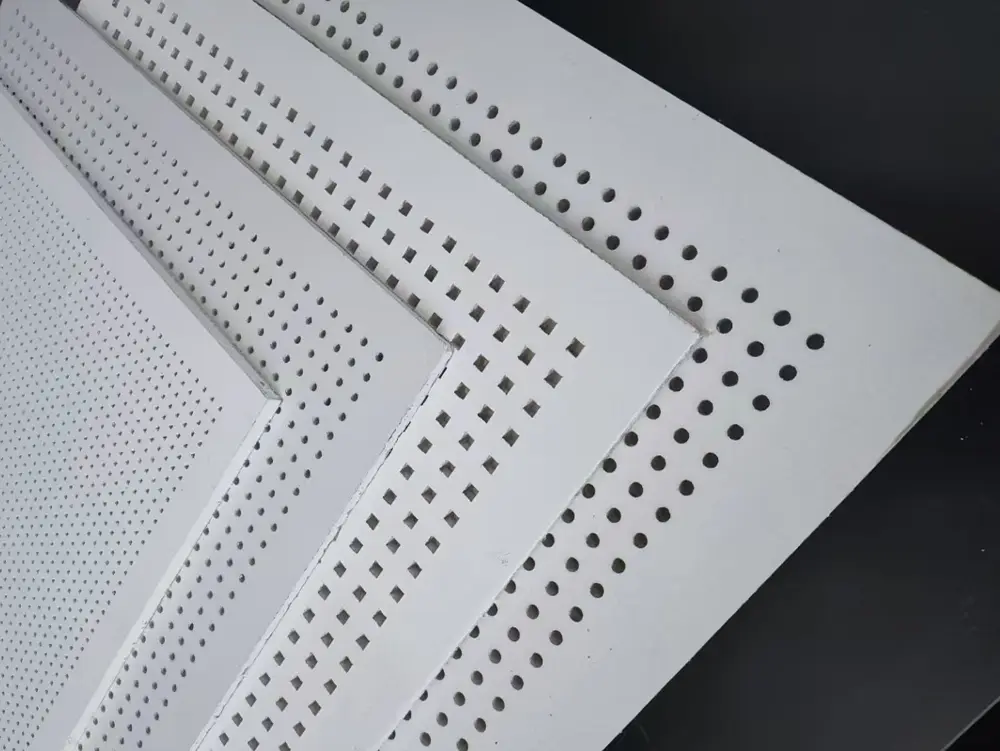

LEAO®Deco Ceiling LEAO® Perforated Ceiling

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel