Solutions for Enhanced Durability with Fiber Cement Board in Global Procurement

In recent years, the construction industry has increasingly recognized the advantages of Fiber Cement Board as a durable, sustainable building material. According to a report by MarketsandMarkets, the global fiber cement market is projected to grow from USD 8.52 billion in 2021 to USD 11.28 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.1%. This surge is largely due to the enhanced durability, fire resistance, and low maintenance costs associated with Fiber Cement Boards, making them an appealing option for diverse applications, including residential and commercial buildings. Additionally, a study published by the Portland Cement Association emphasizes that the use of fiber cement materials can significantly reduce project lifecycle costs—an essential factor in global procurement strategies. As construction stakeholders seek to optimize their supply chains and enhance project resilience, Fiber Cement Board stands out as a leading material choice, aligning durability with eco-friendly practices in a rapidly evolving market.

Innovative Applications of Fiber Cement Board in Sustainable Construction

The fiber cement board has emerged as a pivotal material in sustainable construction, offering numerous innovative applications that enhance both durability and environmental performance. As more architects and builders seek eco-friendly alternatives, fiber cement's resilience to weather, fire, and pests makes it an ideal choice for various structures. This material not only meets the demands of modern construction but also aligns with the growing emphasis on sustainability, making it a smart investment for future projects.

The global fiber cement market is set to experience considerable growth, with estimates suggesting a market value of $15 billion by 2024 and a compound annual growth rate (CAGR) exceeding 5% from 2025 to 2034. This surge in demand is driven by a number of key factors, including increased awareness of sustainable building practices and the need for materials that require less maintenance and longer lifespans. As innovations continue to emerge within the fiber cement industry, its role in sustainable construction is becoming increasingly significant, paving the way for a greener future in building practices around the world.

Durability of Fiber Cement Board vs. Traditional Materials

Evaluating the Cost-Effectiveness of Fiber Cement Solutions in Global Markets

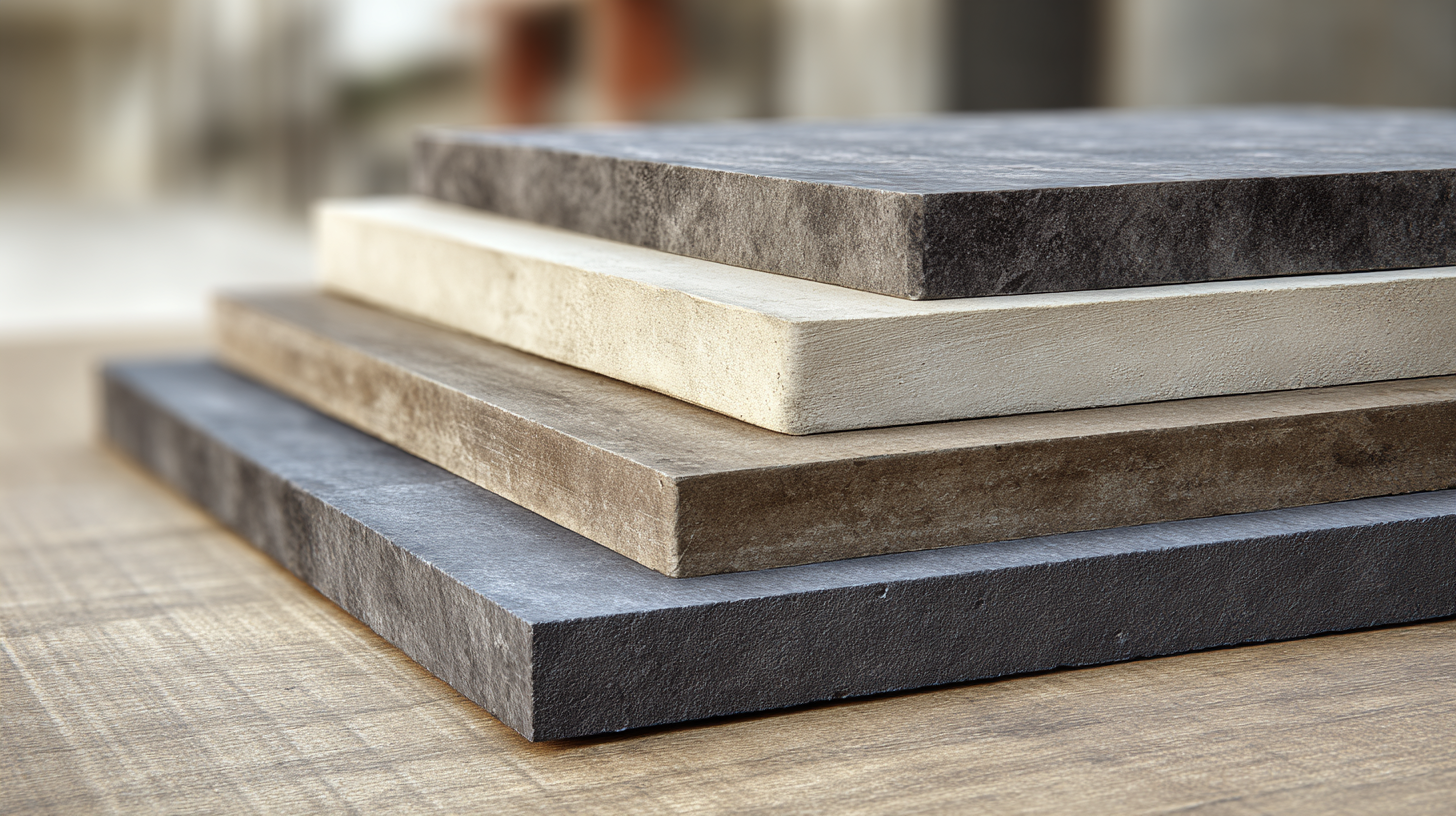

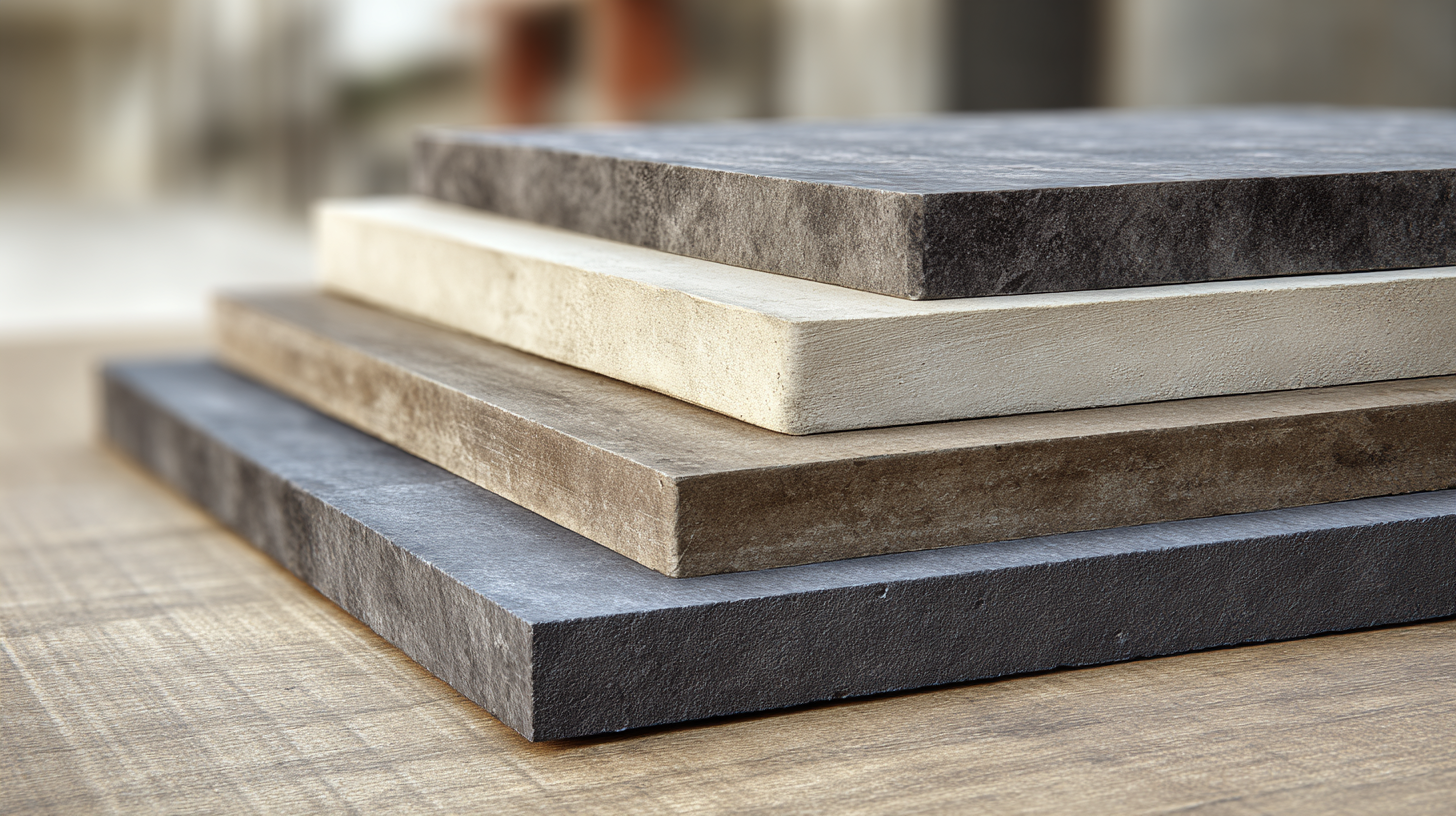

As global markets increasingly seek resilient building materials, fiber cement solutions have emerged as a cost-effective choice for construction projects. The unique composition of fiber cement boards not only enhances durability but also reduces maintenance costs over time. This is particularly advantageous in regions prone to extreme weather, where traditional materials may degrade faster. By evaluating the long-term financial implications of fiber cement products, businesses can make informed decisions that lead to substantial savings on repairs and replacements.

Furthermore, the versatility of fiber cement solutions contributes to their cost-effectiveness. Available in various textures and finishes, these boards can be used across diverse applications, from residential homes to commercial buildings. This adaptability means that companies can procure a single, durable product for multiple uses, minimizing both inventory costs and waste. By analyzing the lifecycle costs associated with fiber cement boards, stakeholders can establish a clear understanding of how this material not only meets but exceeds traditional procurement expectations in terms of both performance and budget.

Comparative Analysis of Fiber Cement and Traditional Building Materials

In the quest for sustainable building solutions, the comparative analysis of

fiber cement board and traditional building materials reveals significant advantages.

According to a report by MarketsandMarkets, the global fiber cement board market

is projected to reach USD 2.32 billion by 2027, driven by a growing demand for

durable and weather-resistant materials. Unlike conventional materials such as wood, which is

susceptible to rot and pests, fiber cement boasts superior resilience, making it ideal for both residential and commercial applications.

Furthermore, the increasing influence of eco-conscious construction practices

is propelling the fiber cement industry forward. A study published by ResearchGate indicates that fiber cement boards can reduce

energy consumption during their lifecycle by up to 25% compared to

traditional materials, thanks to their excellent thermal insulation properties. The

long lifespan and low maintenance requirements of fiber cement not only

contribute to lower life-cycle costs but also minimize the environmental impact associated with frequent renovations and

replacements inherent to traditional materials. This transformative approach in global procurement is paving the way for

more robust and sustainable building practices.

Best Practices for Sourcing High-Quality Fiber Cement Boards Globally

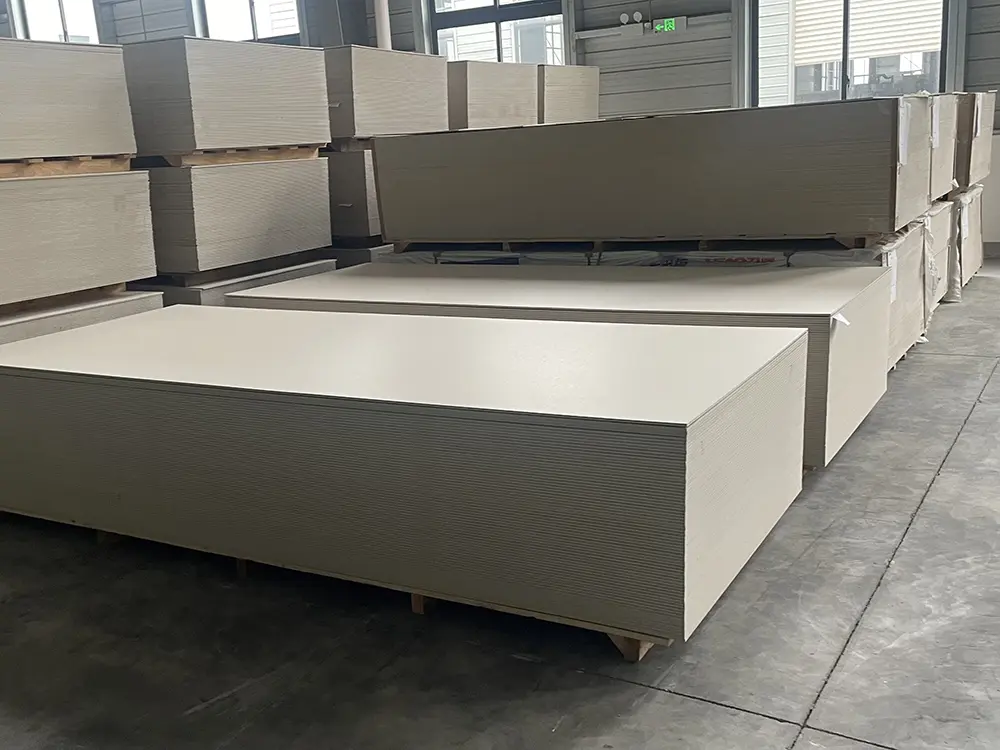

When sourcing high-quality fiber cement boards globally, it is essential to prioritize certain best practices that ensure durability and reliability. First, understanding the material's composition and its manufacturing process is crucial. Engaging suppliers that utilize advanced technology and adhere to strict quality control standards can significantly impact the final product's performance. Buyers should request detailed information on the board’s specifications, including its ratio of cement, cellulose fibers, and additives, which contribute to its strength and longevity.

When sourcing high-quality fiber cement boards globally, it is essential to prioritize certain best practices that ensure durability and reliability. First, understanding the material's composition and its manufacturing process is crucial. Engaging suppliers that utilize advanced technology and adhere to strict quality control standards can significantly impact the final product's performance. Buyers should request detailed information on the board’s specifications, including its ratio of cement, cellulose fibers, and additives, which contribute to its strength and longevity.

Another important practice involves establishing strong relationships with trusted manufacturers and distributors. Building these connections can lead to better pricing, consistent supply, and access to the latest innovations in fiber cement technology. Conducting thorough due diligence, including on-site visits to manufacturing facilities, can provide insight into a supplier’s operational capabilities and commitment to quality. Furthermore, considering local regulations and certifications can help ensure that the fiber cement boards meet the standards required for various global markets. By focusing on these best practices, businesses can enhance their procurement processes and significantly elevate the performance of their projects.

Future Trends in Fiber Cement Technology and Their Market Implications

The future of fiber cement technology is set to revolutionize the construction and building materials market, as innovations continue to enhance performance, sustainability, and aesthetic appeal. With a growing emphasis on durability, manufacturers are investing in advanced formulations that leverage the inherent strength of fiber cement, making it resistant to moisture, fire, and pests. These advancements not only cater to the evolving demands of contractors but also align with global sustainability initiatives, encouraging reduced environmental impact throughout the lifecycle of the products.

**Tip:** When considering fiber cement solutions for your next project, keep an eye out for products that integrate recycled materials. This not only boosts your project's sustainability credentials but can also improve performance in various environmental conditions.

As these technologies progress, market implications include shifts in procurement strategies, with businesses seeking reliable suppliers who offer cutting-edge products. The rise of smart technology in manufacturing processes could also lead to more customized solutions that better fit the specific needs of consumers, thus fostering a more responsive marketplace.

**Tip:** Stay informed about the latest advancements by attending industry conferences and subscribing to relevant trade publications. Networking with suppliers and other professionals can provide valuable insights into upcoming trends and help you make more informed purchasing decisions.

Solutions for Enhanced Durability with Fiber Cement Board in Global Procurement - Future Trends in Fiber Cement Technology and Their Market Implications

| Dimension |

Current Status |

Future Trends |

Market Implications |

| Material Properties |

High durability, moisture resistance |

Improved impact and fire resistance |

Increased demand in construction sector |

| Manufacturing Techniques |

Traditional methods prevalent |

Automation and eco-friendly processes |

Cost reduction and sustainability focus |

| Design Flexibility |

Limited aesthetic options |

Customization in shapes and textures |

Broader application in architectural designs |

| Global Market Trends |

Stable growth in mature markets |

Rapid expansion in emerging economies |

Increased competition and innovation |

| Regulatory Framework |

Strict building codes exist |

Advancements in material standards |

New opportunities for compliant products |

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

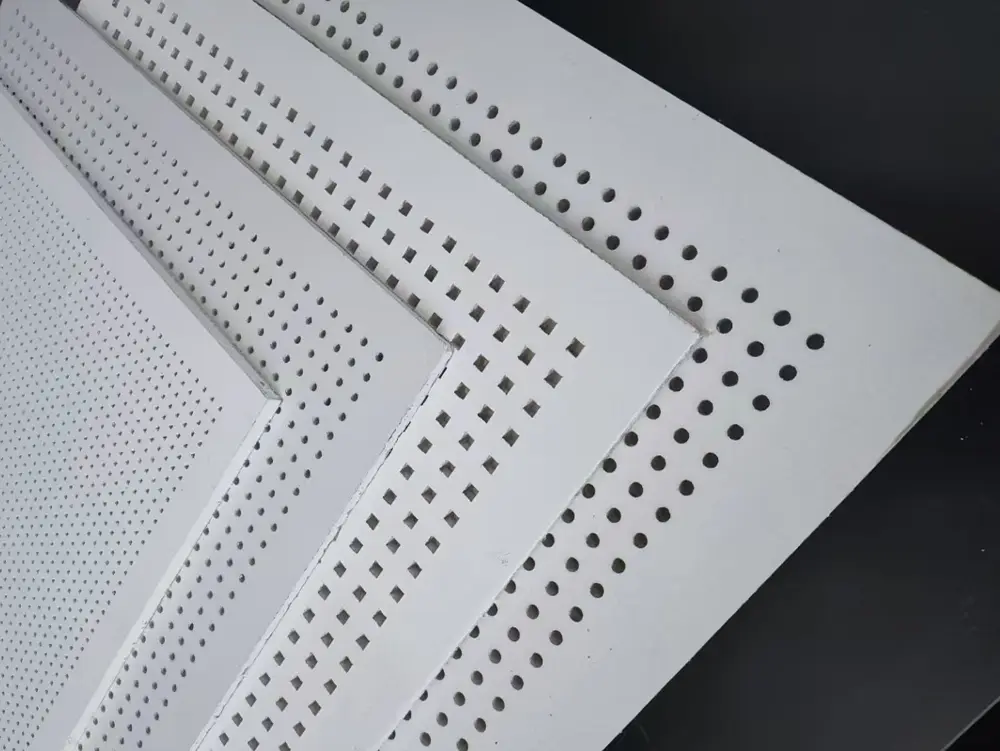

LEAO®Deco Ceiling LEAO® Perforated Ceiling

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel

When sourcing high-quality fiber cement boards globally, it is essential to prioritize certain best practices that ensure durability and reliability. First, understanding the material's composition and its manufacturing process is crucial. Engaging suppliers that utilize advanced technology and adhere to strict quality control standards can significantly impact the final product's performance. Buyers should request detailed information on the board’s specifications, including its ratio of cement, cellulose fibers, and additives, which contribute to its strength and longevity.

When sourcing high-quality fiber cement boards globally, it is essential to prioritize certain best practices that ensure durability and reliability. First, understanding the material's composition and its manufacturing process is crucial. Engaging suppliers that utilize advanced technology and adhere to strict quality control standards can significantly impact the final product's performance. Buyers should request detailed information on the board’s specifications, including its ratio of cement, cellulose fibers, and additives, which contribute to its strength and longevity.