What You Need to Know About Digital Print Board Variations

In the ever-evolving world of digital printing, understanding the intricacies of

Digital Print Board variations is crucial for achieving

optimal results. As businesses and individuals increasingly turn to digital solutions for their printing needs,

the types and specifications of these print boards can significantly impact the quality, durability, and

overall effectiveness of the final product. This blog aims to explore the various Digital Print Board

options available, highlighting important tips and considerations that can help you make informed

decisions. Whether you're looking to enhance your marketing materials, create stunning displays, or simply

understand what sets each Digital Print Board apart, our insights will guide you through the complexities

of this essential component in the digital printing landscape.

Understanding the Importance of Digital Print Board Variations in Production

In the era of the Fourth Industrial Revolution, understanding digital print board variations is crucial for modern production processes. These variations not only enhance the quality and efficiency of printed materials but also align with the broader shifts in technology that are reshaping industries. As businesses integrate sophisticated digital technologies, the ability to adapt and optimize print board designs becomes essential. This adaptability can lead to improved production workflows and better resource management, ultimately resulting in higher quality outputs at reduced costs.

Moreover, as generative AI continues to advance, its application in digital printing will further revolutionize how print boards are produced. By leveraging AI, companies can enhance productivity, creating designs that are not only more innovative but also tailored to meet specific market demands. However, this technological progress also raises concerns about the potential displacement of human workers. It is imperative for organizations to strategically balance the integration of AI with workforce development to ensure that the benefits of digital print board variations can be maximized without compromising employment opportunities in the sector. This dynamic interplay between technology and human skills will shape the future of production in the coming years.

Understanding Digital Print Board Variations

Key Challenges in Achieving Consistent Quality Across Print Board Types

In the world of digital printing, achieving consistent quality across various print board types presents significant challenges. A recent study by Smithers Pira highlighted that the digital print market is expected to grow to $187 billion by 2024, driven by advancements in technology and increasing demand for customized solutions. However, with this growth comes the complexity of maintaining high-quality output across different substrates, such as paper, cardboard, and specialty materials. Each substrate interacts differently with ink, affecting color accuracy and adhesion, which can lead to variations in print quality that brands cannot afford.

One of the key challenges lies in the variability of material characteristics, including texture, absorbency, and thickness. According to a report from the Printing Industries of America, 30% of print service providers identify substrate-related issues as a primary cause of quality inconsistency. Furthermore, variations in digital printing technologies, such as inkjet vs. laser processes, add another layer of complexity. It is crucial for printers to invest in robust quality control measures and employ advanced calibration techniques to mitigate these issues, ensuring that they can deliver reliable, high-quality results regardless of the print board type used.

Analyzing Market Trends: The Demands for Customized Digital Print Solutions

As the global market for customized packaging continues to expand, digital print solutions are emerging as a key player in meeting diverse consumer demands. In 2023, the global customized packaging market is valued at approximately $43.88 billion, and it is projected to grow steadily, reaching $71.1 billion by 2032. This growth reflects a significant shift in consumer preferences towards personalized packaging that enhances brand experience and engages customers more effectively.

To successfully navigate the rise of customized digital print solutions, companies should focus on a few essential strategies. First, investing in high-quality digital printing technologies will enable businesses to offer a wider range of custom options, accommodating everything from variable data printing to intricate designs that resonate with customers. Second, staying informed about market trends and consumer preferences is crucial; conducting regular surveys can provide insights into what customers truly desire in their packaging solutions.

Tip: To enhance customer engagement, consider integrating QR codes or unique designs into packaging, allowing consumers to interact and share their experiences on social media. This not only promotes the brand but also creates a sense of community among consumers. Moreover, leveraging sustainable materials in digital printing can meet the growing demand for eco-friendly packaging, appealing to environmentally conscious consumers.

Comparative Study: Cost Implications of Different Digital Print Board Materials

When considering digital print board materials, the cost implications can vary significantly based on the type of substrate used. For instance, rigid boards such as PVC and foam core typically come with a higher price tag compared to flexible materials like vinyl. While foam core boards might be more affordable, their lower durability can lead to additional costs over time if replacements are frequently needed. This underscores the importance of not only looking at the initial investment but also evaluating the long-term value of each material.

Another factor to consider is the intended application of the printed boards. High-end materials like acrylic and aluminum composites, while more expensive, often yield superior print quality and longevity, making them ideal for professional displays or outdoor usage. On the other hand, budget-friendly options may be suitable for temporary projects, where the costs need to be kept minimal. Ultimately, understanding both the short-term and long-term financial implications of different digital print board materials is essential for making an informed choice that aligns with project goals and budget constraints.

Future Innovations: Enhancing Durability and Sustainability in Digital Print Technology

The future of digital print technology is evolving rapidly, particularly with innovations aimed at enhancing durability and sustainability. According to recent industry reports, the global synthetic paper market, valued at $1.25 billion in 2022, is projected to reach $2.5 billion by 2032, reflecting a compound annual growth rate (CAGR) of over 7.5%. This growth underscores a significant demand for materials that not only cater to high-quality printing needs but also align with sustainability goals.

Furthermore, the market for synthetic leather products is set to experience considerable momentum. Predicted growth within this sector is driven by increasing applications in various industries, including fashion and automotive, alongside rising consumer awareness about environmental impacts. The report indicates that the synthetic leather market is expected to expand significantly over the next decade, fueled by advancements in biodegradable materials and more eco-friendly production processes. Thus, as businesses pivot towards these innovative solutions, enhanced durability and sustainability are becoming critical factors in shaping the future landscape of digital print technology.

What You Need to Know About Digital Print Board Variations - Future Innovations: Enhancing Durability and Sustainability in Digital Print Technology

| Feature |

Description |

Benefits |

Sustainability Aspect |

| Ink Durability |

High resistance to fading and scratching. |

Longer lifespan of printed materials. |

Reduced waste by minimizing reprints. |

| Material Variability |

Ability to print on diverse substrates. |

Versatility in product applications. |

Use of recycled materials where possible. |

| Print Speed |

Fast production times for large runs. |

Increased efficiency and reduced labor costs. |

Less energy consumption per unit produced. |

| Color Accuracy |

Precision in matching colors across prints. |

Enhanced customer satisfaction with quality. |

Minimal ink wastage through precise applications. |

| Eco-Friendly Inks |

Water-based and soy-based inks. |

Safer for the environment and users. |

Supports sustainable sourcing and production. |

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

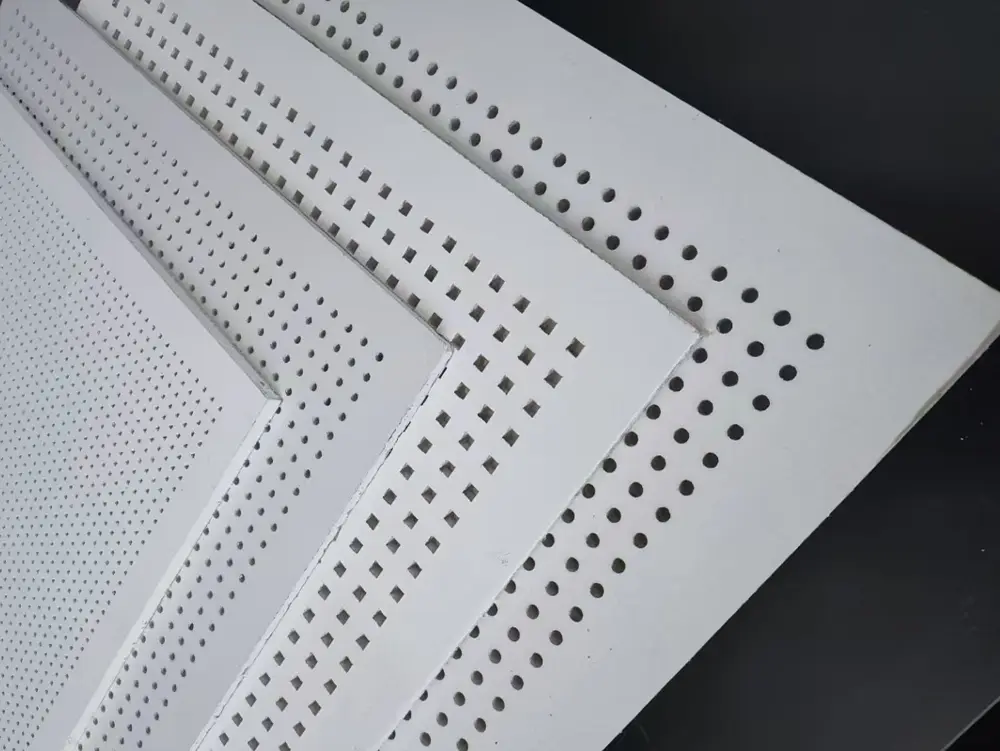

LEAO®Deco Ceiling LEAO® Perforated Ceiling

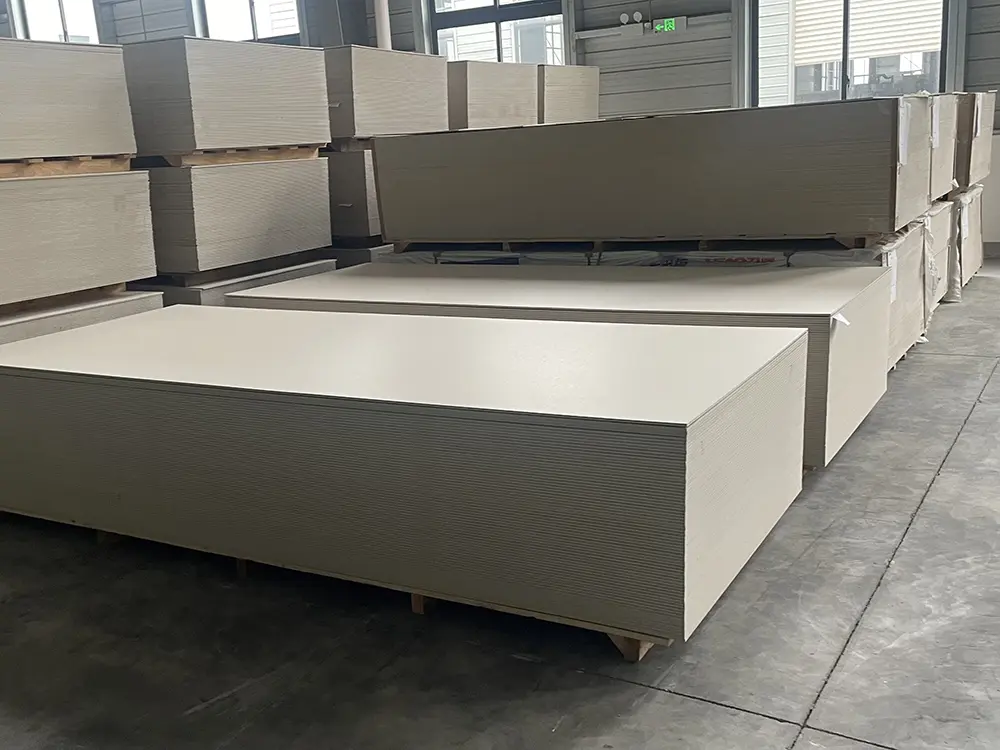

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel