How to Choose the Best Compressed Fiber Cement Board for Your Project

When embarking on a construction or renovation project, selecting the right materials is crucial for achieving durability and aesthetic appeal. Among the various options available, Compressed Fiber Cement Board has garnered significant attention due to its impressive performance data. According to a report by MarketsandMarkets, the global fiber cement board market is projected to grow from USD 12.5 billion in 2020 to USD 19.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 9.1%. This growth underscores the increasing reliance on materials that offer resilience against fire, moisture, and pests. Not only is Compressed Fiber Cement Board versatile and eco-friendly, but it also meets high standards for structural integrity and resistance to weathering. Choosing the best Compressed Fiber Cement Board for your project involves understanding its varied applications and benefits, ensuring you make an informed decision that aligns with your specific needs.

When embarking on a construction or renovation project, selecting the right materials is crucial for achieving durability and aesthetic appeal. Among the various options available, Compressed Fiber Cement Board has garnered significant attention due to its impressive performance data. According to a report by MarketsandMarkets, the global fiber cement board market is projected to grow from USD 12.5 billion in 2020 to USD 19.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 9.1%. This growth underscores the increasing reliance on materials that offer resilience against fire, moisture, and pests. Not only is Compressed Fiber Cement Board versatile and eco-friendly, but it also meets high standards for structural integrity and resistance to weathering. Choosing the best Compressed Fiber Cement Board for your project involves understanding its varied applications and benefits, ensuring you make an informed decision that aligns with your specific needs.

Understanding the Basics of Compressed Fiber Cement Board

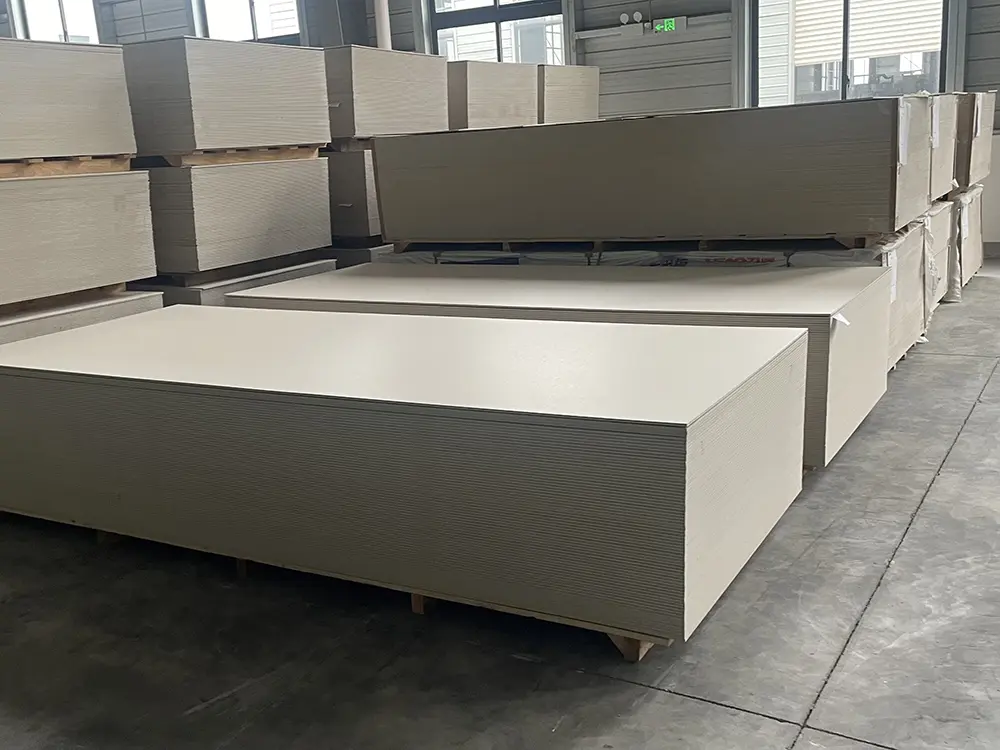

When considering the best compressed fiber cement board for your project, it is essential to first understand what these materials are and their core characteristics. Compressed fiber cement boards are engineered products made from a blend of cement, cellulose fibers, and sometimes reinforcing agents. This unique combination results in a durable and moisture-resistant building material that is ideal for a wide range of applications, including exterior cladding and interior partitions.

Moreover, the

innovation in sustainable materials, such as bamboo-based composites, highlights the growing trend towards eco-friendly options in construction. Understanding the bonding processes and sustainable applications of these materials can provide valuable insights into selecting the most suitable compressed fiber cement board for your needs. A board's sustainability, performance under various environmental conditions, and durability can influence the overall success of your project. Integrating knowledge of both fiber cement and bamboo composites can lead to more informed choices in material selection, ensuring

longevity and resilience in your construction endeavors.

Key Factors to Consider When Choosing Fiber Cement Boards

When selecting the best compressed fiber cement board for your project, there are several key factors to consider. Firstly, the thickness of the board is critical. Generally, boards ranging from 6mm to 12mm are available, with thicker options providing enhanced durability and resistance to impact and moisture. According to a report by Research and Markets, the global fiber cement board market is projected to reach USD 20.5 billion by 2025, driven by the growing demand for durable and low-maintenance building materials.

Another important aspect is the board’s density, which typically varies from 900 to 1300 kg/m³. Higher density boards offer superior performance in terms of fire resistance and insulation. The Fire Protection Association emphasizes that fiber cement boards can withstand high temperatures, making them suitable for both residential and commercial applications. Furthermore, consider the finish and aesthetic appeal of the boards, as they are available in various textures and colors that can enhance the overall design of your project. Selecting the right compressed fiber cement board involves balancing these factors to meet both functional and aesthetic needs.

How to Choose the Best Compressed Fiber Cement Board for Your Project - Key Factors to Consider When Choosing Fiber Cement Boards

| Factor |

Description |

Importance Level |

| Material Quality |

Assess the durability, resistance to moisture, and fire rating of the boards. |

High |

| Thickness |

The thickness affects insulation and soundproofing; choose based on application needs. |

Medium |

| Surface Finish |

Consider if pre-finished or primed boards are necessary based on aesthetics. |

Low |

| Environmental Impact |

Choose boards made from sustainable sources to reduce ecological footprint. |

Medium |

| Cost |

Evaluate the overall budget and compare prices while ensuring quality. |

High |

Comparing Different Brands and Products for Quality Assurance

When selecting compressed fiber cement boards for your project, it's essential to compare different brands and products to ensure quality assurance. Different manufacturers may offer varying formulations and production processes, which can significantly impact the board's durability, resistance to moisture, and overall performance. For example, brands known for their innovative technology may provide boards with enhanced structural integrity, while others might focus on eco-friendly materials that are less harmful to the environment.

It’s also crucial to examine specific product attributes such as thickness, density, and surface finish. Some boards are designed for particular applications, such as exterior facades or interior wall linings, which can influence your choice depending on your specific project requirements. Reading customer reviews and consulting product certifications can further assist in assessing the reliability of different brands. By taking the time to compare these factors, you can select a compressed fiber cement board that not only meets your design standards but also guarantees quality and longevity.

Comparison of Compressed Fiber Cement Board Properties

Installation Tips and Best Practices for Fiber Cement Boards

When it comes to installing fiber cement boards, following best practices can significantly enhance the durability and aesthetics of your project. First, ensure that you start with a clean and dry surface. This is crucial for the adhesive or fasteners to bond effectively. Additionally, always check the manufacturer's recommendations for the appropriate spacing of your panels to avoid warping or buckling over time.

Another essential tip is to use the right tools for cutting and fixing the boards. A carbide-tipped blade works best for clean cuts, minimizing dust and ensuring precise edges. When fastening, opt for corrosion-resistant screws specifically designed for fiber cement. This will help prevent rust and prolong the lifespan of your installation.

Lastly, always leave appropriate gaps between the boards. This allows for thermal expansion and contraction, which is vital for maintaining the integrity of the installation. Utilize caulk or a backing rod to fill in these gaps to keep out moisture and pests, ensuring a long-lasting finish for your project.

Sustainability and Environmental Impact of Fiber Cement Boards

The environmental sustainability of the cement industry has been a topic of concern for many years, particularly as projects increasingly demand eco-friendly building materials. One innovative solution gaining traction is fiber cement boards, which offer a multitude of benefits in terms of durability and minimal environmental impact. By utilizing sustainable practices in their production, these boards reduce the carbon footprint traditionally associated with cement manufacturing.

Fiber cement facades exemplify how the architecture sector can embrace sustainability without compromising on performance. Many options on the market now feature Cradle to Cradle Certified® accreditation, ensuring that they meet strict standards for environmental responsibility. These materials not only provide excellent longevity and resistance to various elements, but they also contribute positively to indoor and outdoor environments. As the industry continues to innovate, the potential for further advancements in sustainable practices becomes increasingly promising, setting a new standard in construction that prioritizes both aesthetic appeal and ecological health.

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

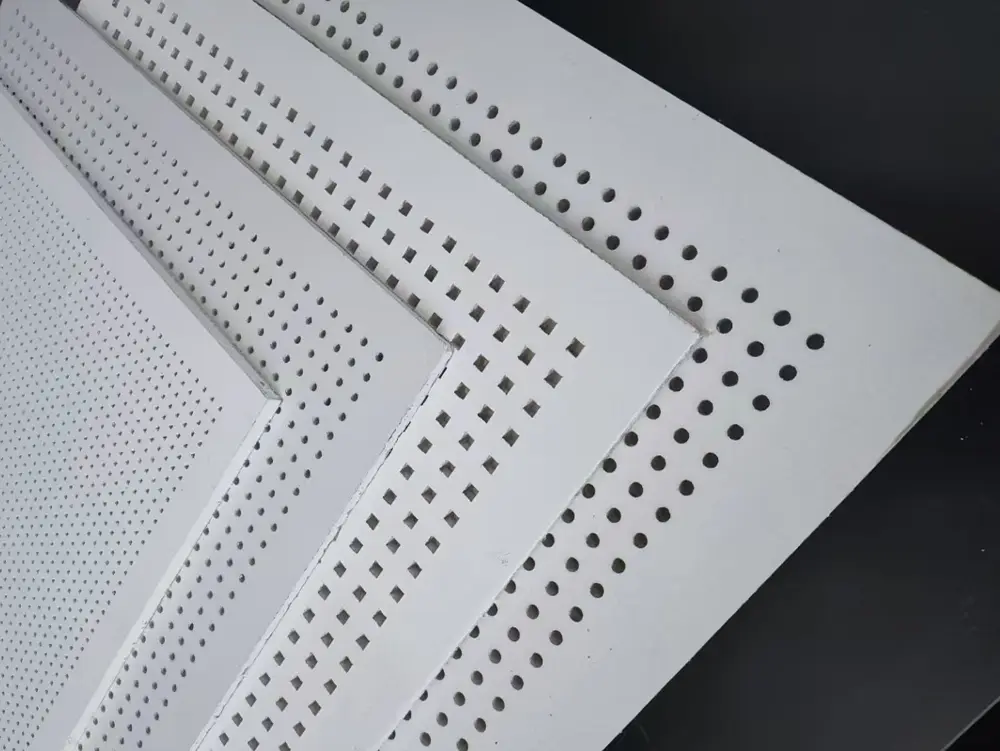

LEAO®Deco Ceiling LEAO® Perforated Ceiling

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel When embarking on a construction or renovation project, selecting the right materials is crucial for achieving

When embarking on a construction or renovation project, selecting the right materials is crucial for achieving