Addressing Common Issues with Best Fiber Cement Woodgrain Boards for Your Projects

In recent years, the demand for Fiber Cement Woodgrain Boards has surged as homeowners and builders alike have recognized their exceptional durability and aesthetic appeal. However, along with their popularity, certain common issues have arisen, particularly regarding after-sales service advantages and maintenance costs. As a material that promises both the charm of natural wood and the resilience of cement, it’s essential to address these concerns to ensure that projects utilizing Fiber Cement Woodgrain Boards deliver long-term satisfaction.

Understanding the nuances of after-sales support can transform a potential challenge into a seamless experience, while being informed about maintenance requirements can help in budgeting and planning effectively. This blog aims to explore these facets in detail, providing valuable insights for anyone looking to incorporate Fiber Cement Woodgrain Boards into their upcoming projects.

Emerging Trends in Fiber Cement Woodgrain Technology for 2025

As we approach 2025, the field of

fiber cement woodgrain technology

is poised for exciting advancements that promise to enhance both aesthetic appeal and functional performance in building materials.

Emerging trends indicate a shift towards more environmentally friendly production processes, with manufacturers increasingly adopting

sustainable practices. This includes utilizing recycled materials and

reducing harmful emissions, all while maintaining the durability and versatility that fiber cement products are known for.

Additionally, innovations in surface textures and finishes are on the rise, enabling designers to achieve

authentic wood looks without sacrificing the longevity of fiber cement.

The introduction of advanced coating techniques will not only improve the visual appeal but also enhance resistance to weathering,

fading, and other common issues associated with traditional wood products. As these trends unfold, the choice of fiber cement woodgrain boards

will become an increasingly popular option for architects and homeowners seeking a blend of

beauty and lasting performance in their projects.

Key Benefits of Using Fiber Cement Woodgrain Boards in Construction Projects

Fiber cement woodgrain boards are increasingly becoming the go-to choice in construction projects due to their numerous advantages. One of the key benefits is their durability. Unlike traditional wood, fiber cement boards are resistant to rot, insects, and extreme weather conditions. This longevity means fewer replacements and repairs over time, ultimately saving costs for builders and homeowners alike.

Fiber cement woodgrain boards are increasingly becoming the go-to choice in construction projects due to their numerous advantages. One of the key benefits is their durability. Unlike traditional wood, fiber cement boards are resistant to rot, insects, and extreme weather conditions. This longevity means fewer replacements and repairs over time, ultimately saving costs for builders and homeowners alike.

Another significant advantage is the aesthetic appeal these boards provide. The woodgrain texture mimics the warm, natural look of wood while offering the versatility of a modern building material. Available in various colors and finishes, fiber cement woodgrain boards can enhance the visual attractiveness of any project, making them suitable for both residential and commercial applications. Additionally, they require minimal maintenance, allowing for a beautiful façade that stands the test of time without the upkeep associated with real wood.

Moreover, using fiber cement woodgrain boards contributes to more sustainable building practices. Made from environmentally friendly materials, these boards can significantly reduce the impact on forests and promote resource conservation. This makes them an excellent choice for eco-conscious builders looking to combine aesthetic appeal with environmental responsibility in their projects.

Common Issues Faced with Fiber Cement Woodgrain Boards and Solutions

Fiber cement woodgrain boards are becoming increasingly popular in construction and renovation projects due to their durability and aesthetic appeal. However, several common issues can arise, including moisture sensitivity, improper installation, and limited color options. Moisture can cause fiber cement boards to warp or swell if not correctly managed. To counteract this, ensure proper ventilation and consider using products with advanced moisture resistance technologies.

One tip for addressing installation concerns is to follow manufacturer guidelines closely. Inconsistent installation techniques can lead to problems such as gaps, buckling, or premature wear. Engaging only experienced contractors familiar with fiber cement products can mitigate this risk. Additionally, embracing newer options in the market can alleviate color limitations, as many manufacturers now offer a broader range of finishes and styles that cater to modern design preferences.

In recent projects across various sectors, emphasis on innovative materials has shown that fiber cement boards, when selected and installed correctly, can elevate the aesthetic of any structure while providing robust performance against environmental challenges. Consider exploring the latest industry offerings to find solutions that align with your vision and functional needs.

Common Issues with Fiber Cement Woodgrain Boards

Sustainability Considerations for Fiber Cement Woodgrain Products

Fiber cement woodgrain boards are increasingly being recognized for their sustainability, making them an ideal choice for environmentally conscious construction projects. According to a report by the Global Cement and Concrete Association, using fiber cement materials can reduce CO2 emissions by up to 30% compared to traditional wood products. This is largely due to their long lifespan and reduced need for replacement, leading to less waste in landfills.

One of the most significant sustainable features of fiber cement is its resistance to rot, insects, and extreme weather conditions. This durability not only enhances the longevity of your installations but also minimizes the need for chemical treatments that can harm the environment. When selecting fiber cement woodgrain boards, look for products with certifications such as the Forest Stewardship Council (FSC), which ensures responsible sourcing of raw materials.

Tip: When planning your projects, consider integrating recycled materials in your design to further bolster sustainability. Also, conduct a life cycle assessment to evaluate the environmental impact of your building materials. Not only will this benefit the planet, but it can also lead to cost savings and a positive reception from eco-aware clients.

Innovative Applications of Fiber Cement Woodgrain Boards in Modern Architecture

The use of fiber cement woodgrain boards is becoming increasingly prominent in modern architecture, thanks to their versatility and aesthetic appeal. These boards offer an innovative solution that combines the natural look of wood with the durability of fiber cement, making them suitable for a variety of applications, from residential homes to commercial buildings. A recent study by Freedonia Group projects that the demand for fiber cement siding will grow by 4.7% annually, indicating a shift towards sustainable materials that can withstand weather elements while retaining their visual appeal.

Architects and designers are now integrating fiber cement woodgrain boards into facades, accent walls, and even interior designs. Their resilient nature allows them to resist rot and insect damage, a significant advantage over traditional wood. Additionally, according to a report from Research and Markets, the fiber cement market is expected to reach $10 billion by 2025, driven by increased consumer awareness of sustainable building materials. This trend highlights the importance of fiber cement woodgrain boards as a key player in the future of architectural design, blending innovation with functionality for a more sustainable built environment.

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

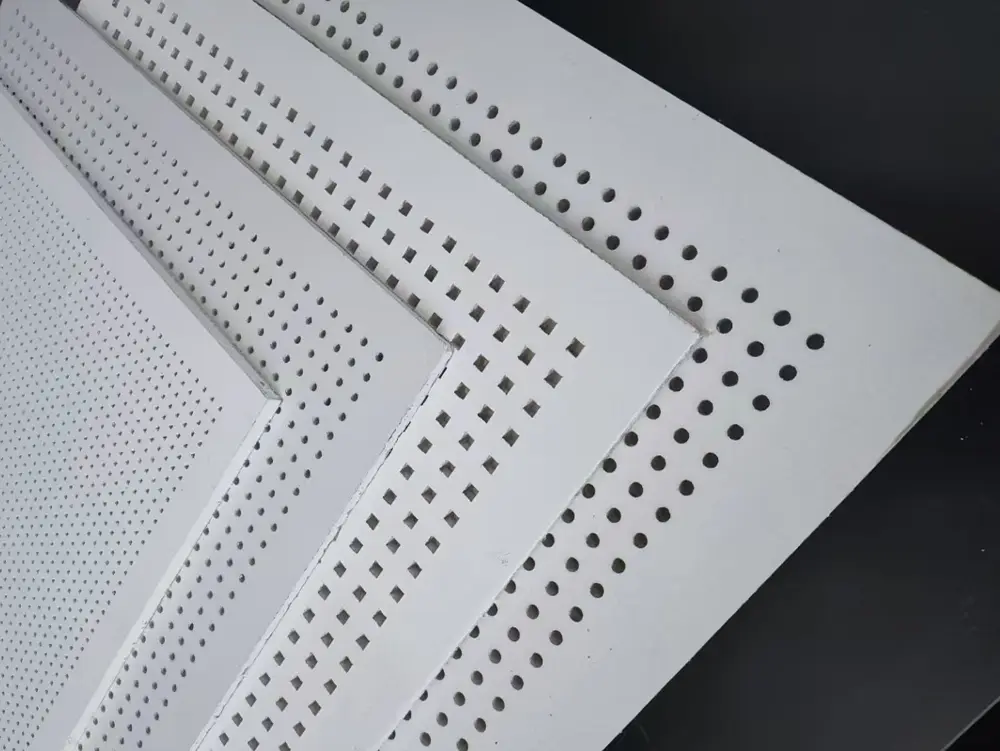

LEAO®Deco Ceiling LEAO® Perforated Ceiling

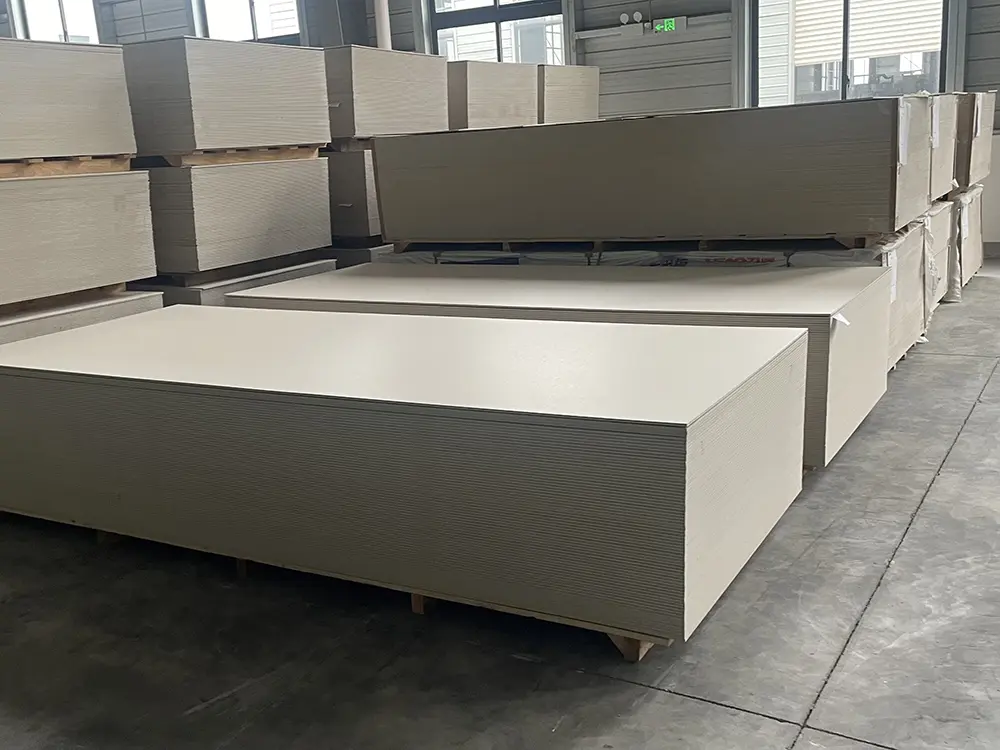

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel